- Great Value: Excellent performance at a cost effective price.

- Excellent Seam Strength: Heat-welded seams provide greater seam strength to taped and other seams.

- Long-term Weathering: Excellent long-term heat and UV resistance.

- Energy Saving: Highly reflective and emissive white surface can help reduce energy costs and urban heat island effect.

- Inherently Flexible: No need for plasticizers.

- Naturally Fungal Resistant: Doesn’t require biocides.

- Versatile Application Methods: Including high-performance roofs requiring high wind uplift, increased puncture resistance, or quick economical systems.

- Home

- Commercial

- TPO

- GAF | TPO

GAF | TPO

Short for thermoplastic polyolefin, TPO is a single-ply roofing membrane that offers excellent performance at a cost-effective price. Heat-welded seams provide superior strength. TPO's long-term heat, UV, and natural fungal resistance, plus flexibility without need for plasticizers also make TPO a reliable low-slope roofing system.

System Benefits

6 great application techniques

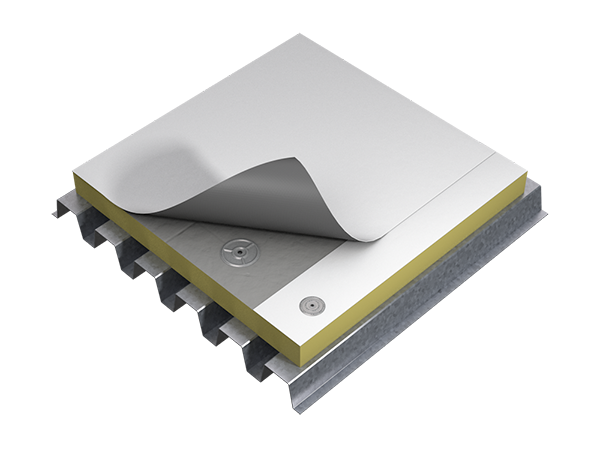

Mechanically Attached Smooth Application

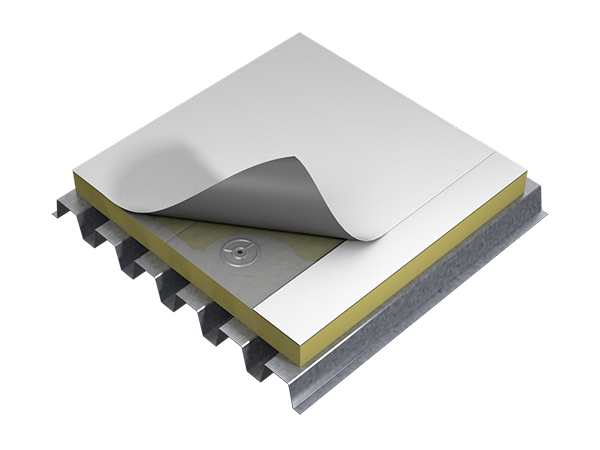

Fully Adhered Smooth Application

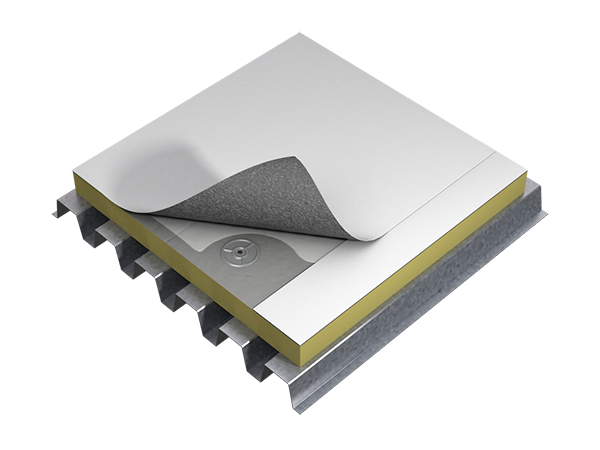

Fully Adhered with WB1b1 Wet Lay-in Fleece Back Application

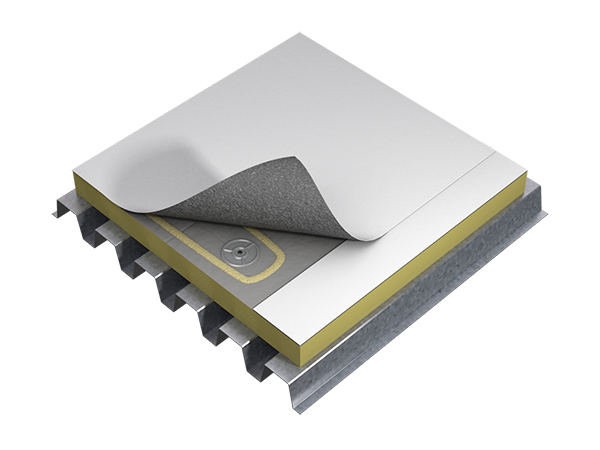

Adhered with Low-Rise Foam Fleece Back Application

Fully Adhered with 2-Part Adhesive Fleece Back Application

Rhinobond System

PRODUCT INFORMATION

Was the best-performing standard TPO in accelerated aging in the largest independent TPO study ever conducted. With over 15 years of proven performance, it can fit many roofing budgets and needs:

- Available in 45, 60, and 80 mil

- Guarantees available up to 30 years*

- 10-ft.-wide sheets can help increase production compared to other roofing technologies

- Different systems available, including mechanically attached, fully adhered, and RhinoBond® Attachment Systems†

MECHANICALLY ATTACHED SMOOTH TPO with Drill-Tec™ Fasteners

Installing smooth TPO with fasteners in a mechanically attached system offers several benefits, including:

- Up to 50% faster installation compared to fully adhered smooth membrane installations

- Reliability and cost effectiveness

- Familiarity with the industry as the most common installation method in single-ply membranes

- Consistent installation in a wide variety of temperatures

- No sprayers or additional capital investments

- A great option for occupied buildings, as there is no odor from adhesives

While fully adhered systems have better wind uplift ratings, a mechanically attached system’s ratings can be increased by modifying the fastening pattern from 12″ on center to 6″on center. Be sure to refer to the GAF Drill-Tec™ Fastening Guide to choose the correct fasteners and plates for your application.

FULLY ADHERED SMOOTH TPO with Traditional Bonding Adhesive

Installing fully adhered EverGuard® Smooth TPO Systems offers several benefits, including:

- Longer guarantees compared to mechanically attached systems

- Excellent wind uplift ratings

- A uniform, smooth appearance

- Familiarity with workers, as this installation is common in the industry

- Minimizes thermal drift while acting as a vapor barrier

FULLY ADHERED FLEECE-BACK TPO with WB181 Wet Lay-in

Installing fleece-back TPO with EverGuard® WB181 Bonding Adhesive offers several benefits, including:

- Up to 50% faster installation time than traditional smooth, fully adhered systems

- Reduced labor costs

- Low-VOC content with little-to-no odor, which reduces the disruption to building occupants

- Additional puncture resistance due to the fleece backing of EverGuard® membrane

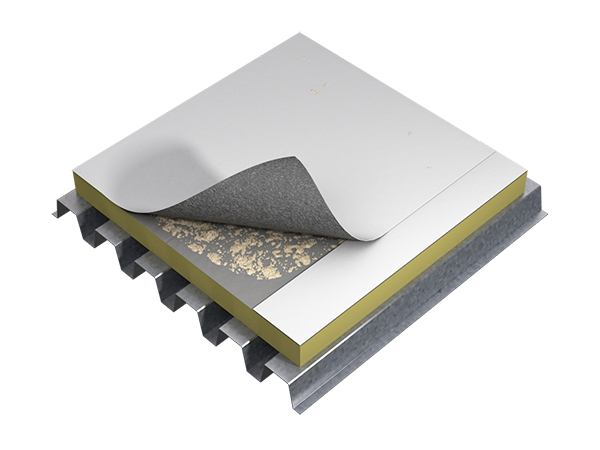

ADHERED FLEECE-BACK TPO with Low-Rise Foam

Installing fleece-back TPO with low-rise foam roofing adhesive offers several benefits, including:

- Up to 50% faster installation time than traditional smooth, fully adhered systems

- Reduced labor costs

- Low-VOC content with little-to-no odor, which reduces the disruption to building occupants

- Additional puncture resistance due to the fleece backing of EverGuard® membrane

FULLY ADHERED FLEECE-BACK TPO with GAF 2-Part Roofing Adhesive

Installing fleece-back TPO with GAF 2-Part Roofing Adhesive offers several benefits, including:

- Up to 50% faster installation than traditional fully adhered, smooth systems (it’s as easy as watering your lawn)

- I ncreased productivity and smaller crews versus other attachment methods

- Up to 20 squares of coverage per set of containers

- Longer guarantees compared to mechanically attached systems

- No expensive equipment or maintenance

- Excellent wind uplift performance

- I ncreased puncture resistance due to the fleece backing of EverGuard® membrane

- Low-VOC content with low odor

- Substrate, membrane, and outside temperatures must be 40°F (4.4°C) and rising. Application temperatures above 50°F (10°C) are recommended to allow easier adhesive application.

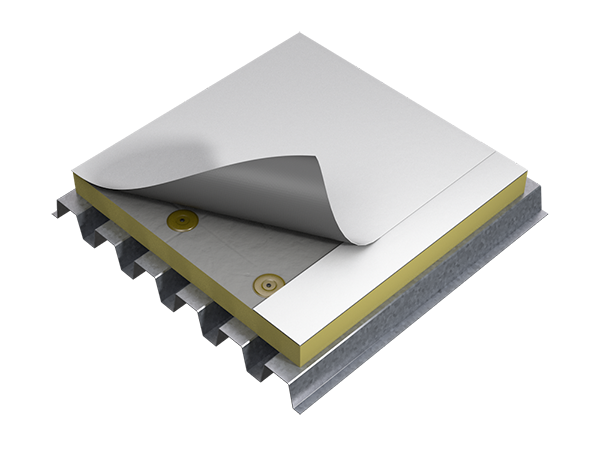

RHINOBOND® SYSTEM

Installing smooth TPO with the RhinoBond®† Attachment System offers several benefits, including:

- A fast and easy installation

- Smaller crews and install time, with up to 50% faster installation by adding a second machine

- Quick dry-in, as membrane seams can be welded before RhinoBond® Plates are bonded

Warranty Program

Please visit GAF’s website for information pertaining Evergaurd TPO warranties.